Purpose and capabilities:

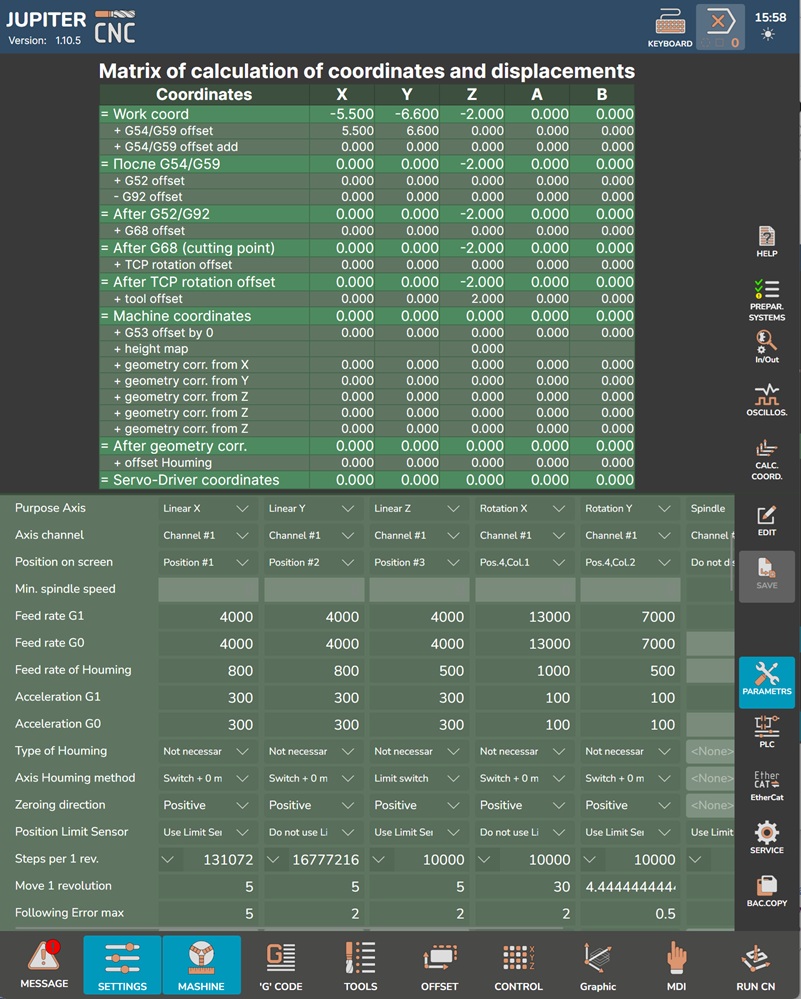

• The program is designed to control a milling machine• 3 linear axes + up to 2 rotary axes

• Various machine kinematics XYZ-A/B/AC/BC

• Rotational axes of the table/chuck or spindle

• RTCP mode (Rotate Tool Point Center - a mode for holding the center of the tool cutting point when the axes rotate)

• 2 parallel channels (up to 5 axes in each)

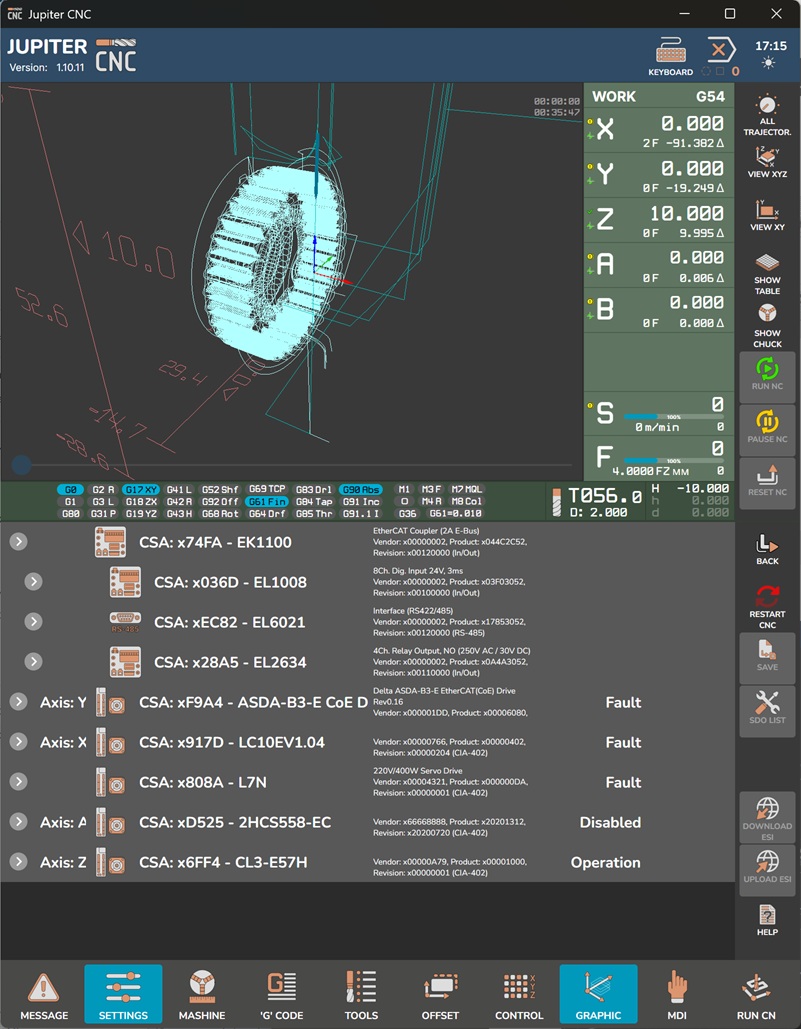

• Control of axes and inputs/outputs via the EtherCat/GRBL protocol

• Control of inputs/outputs via the MODBUS RTU protocol.

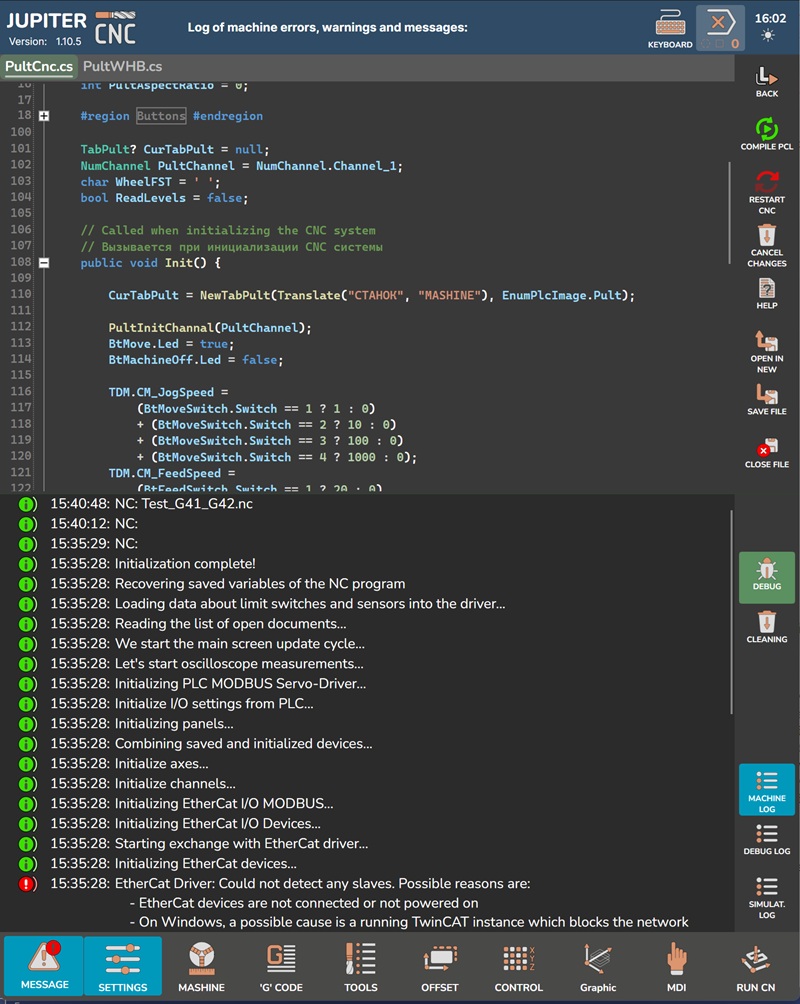

• PLC control of the machine's electrical automation with the ability to be configured by the user

• MPG remote control

• The ability to add custom "Software" control panels for various equipment

• Ability to control the "Automatic Tool Change" and other machine auxiliary devices via a programmable PLC.

• Machine geometry correction.

• OS: Windows or Linux (Android and iOS will be available later)

• Requires running the EtherCat driver on a Mini-PC running Linux (On Linux, it is possible to run the CNC and driver on the same PC).

• Vertical monitor orientation is strongly recommended.

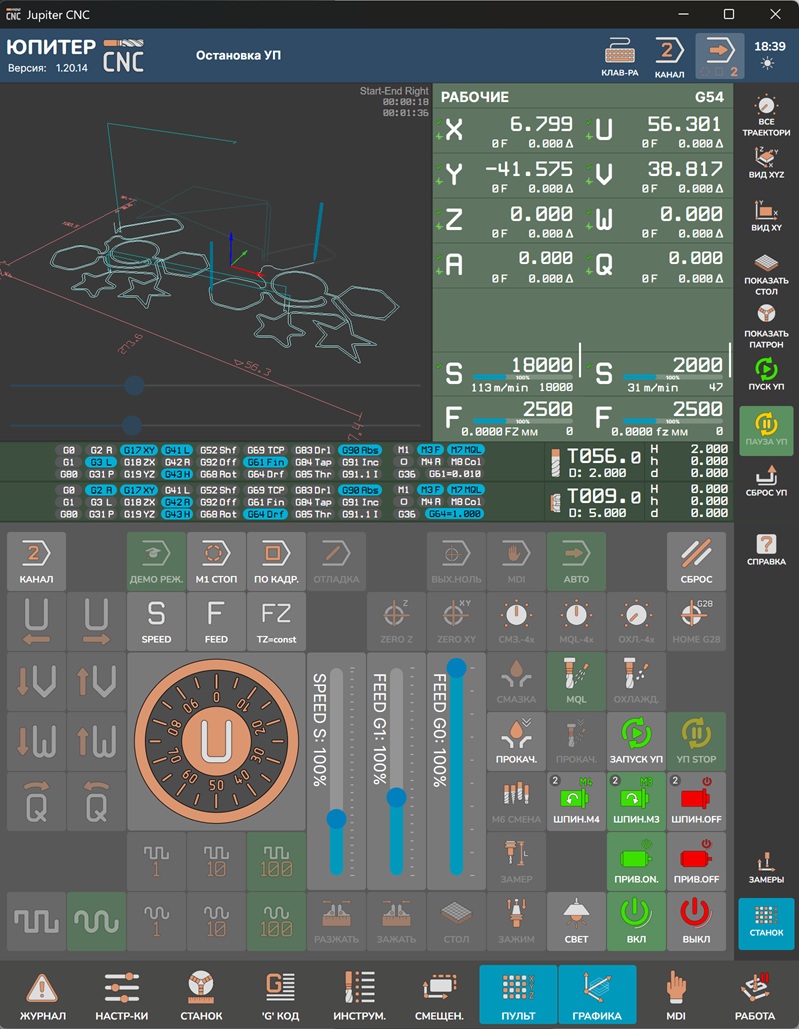

Machine control panel:

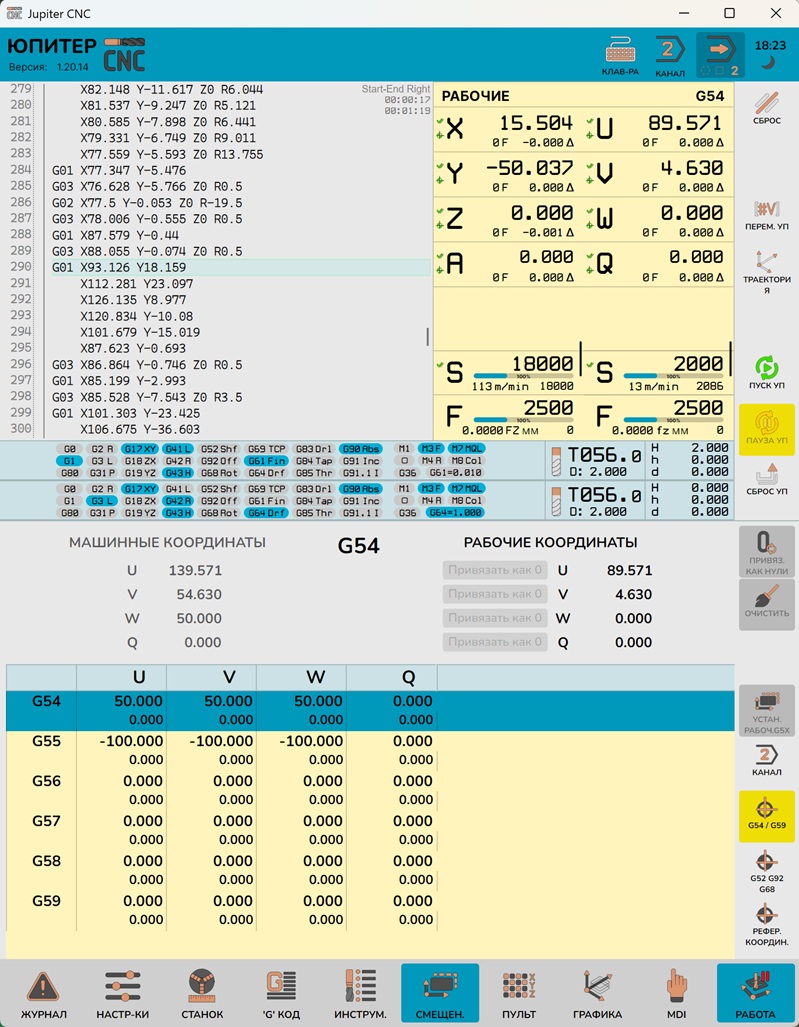

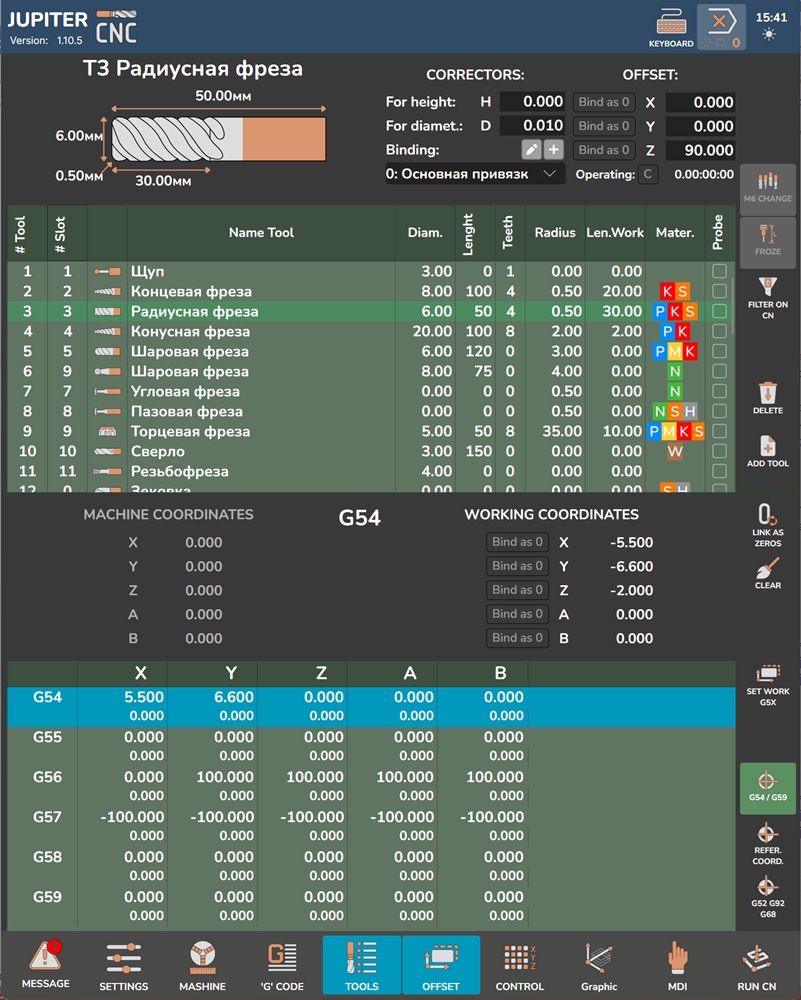

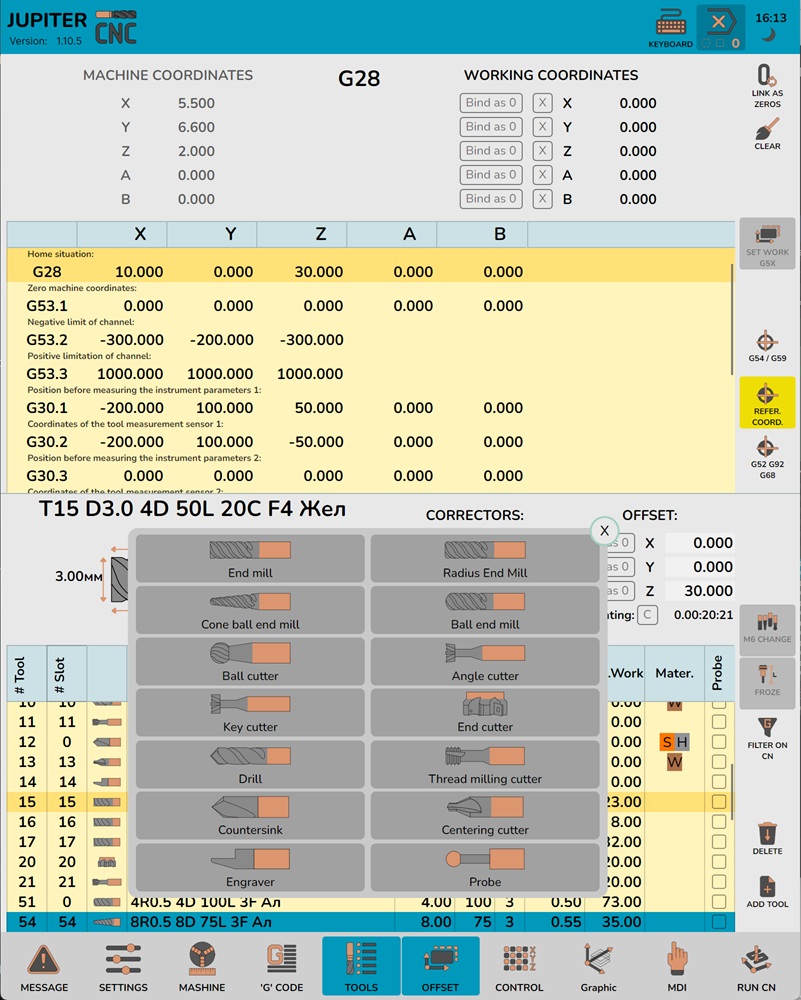

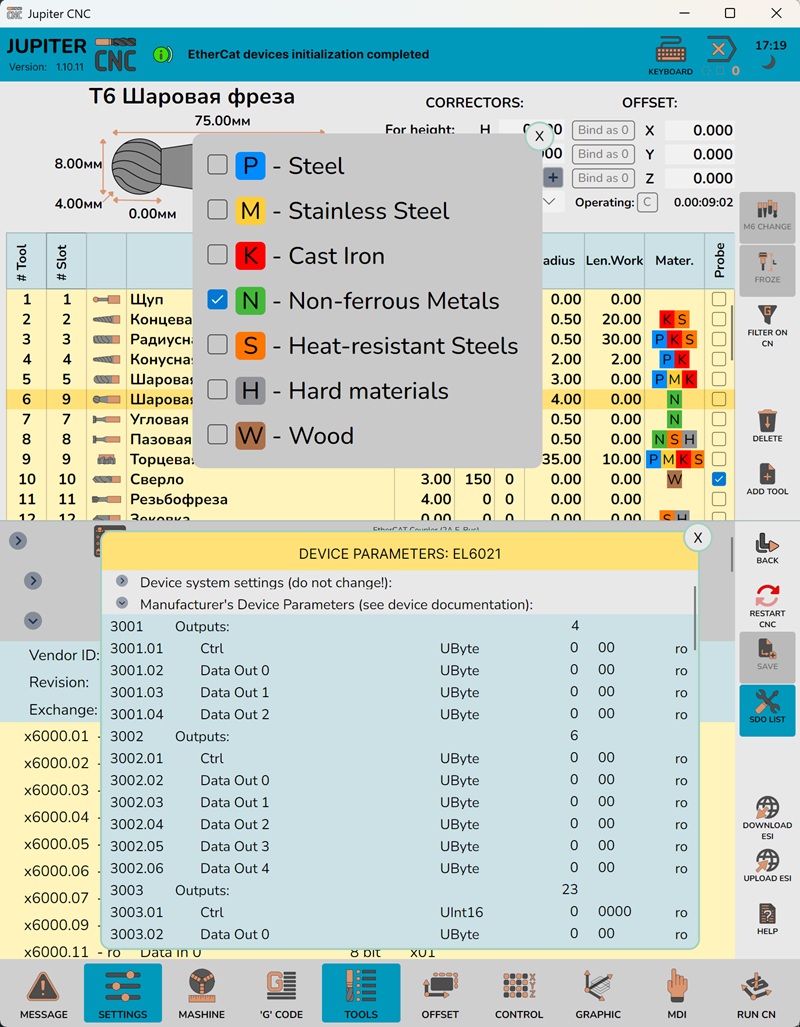

Tools and offsets for G54/59:

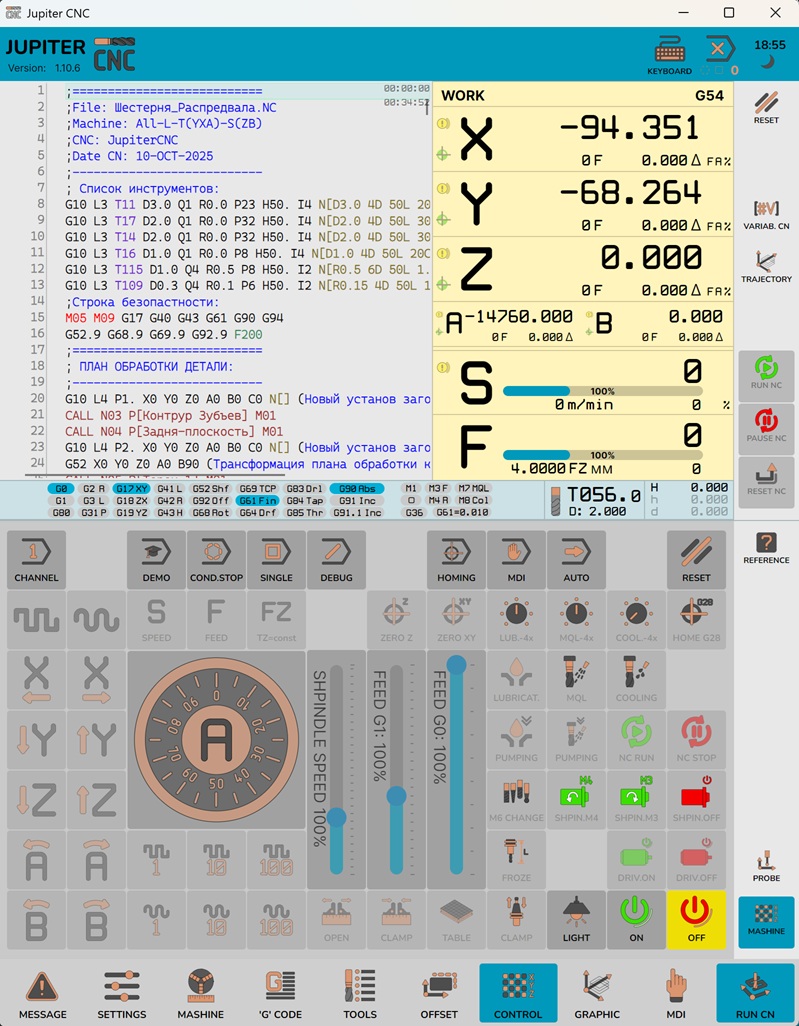

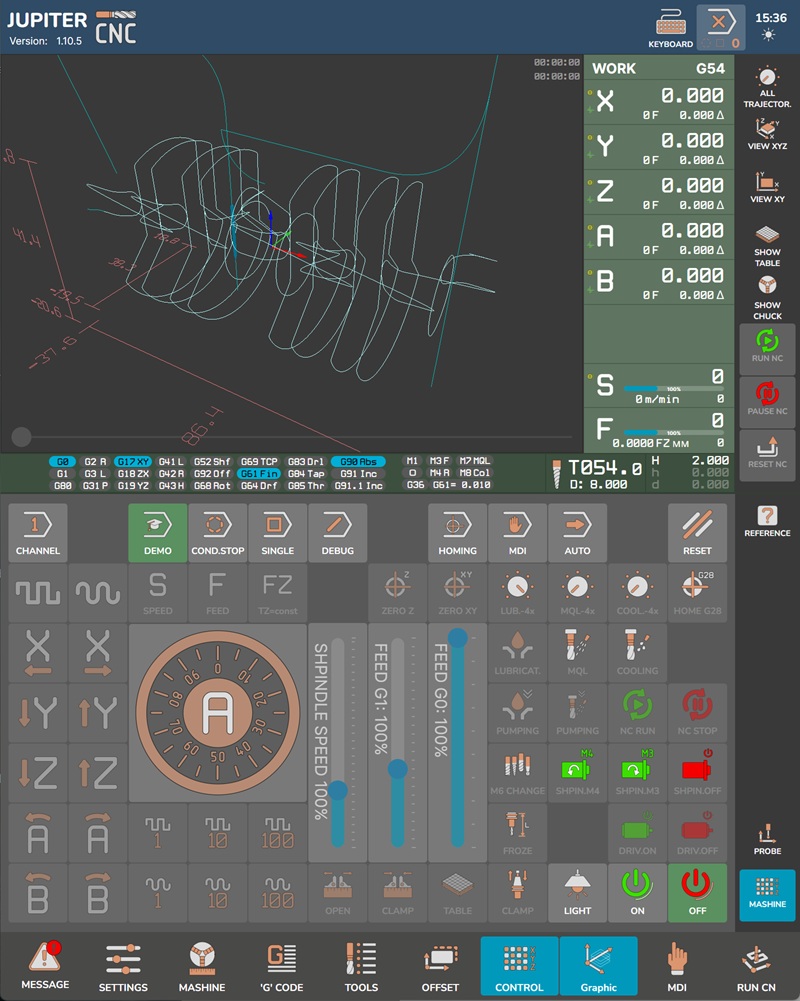

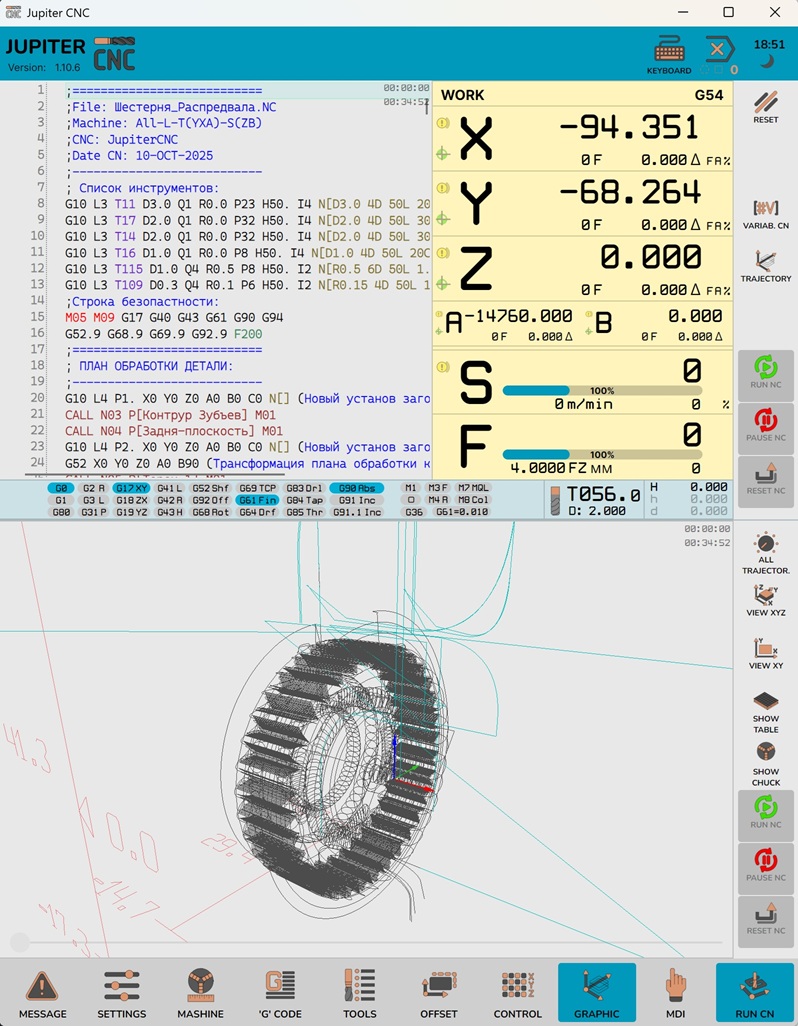

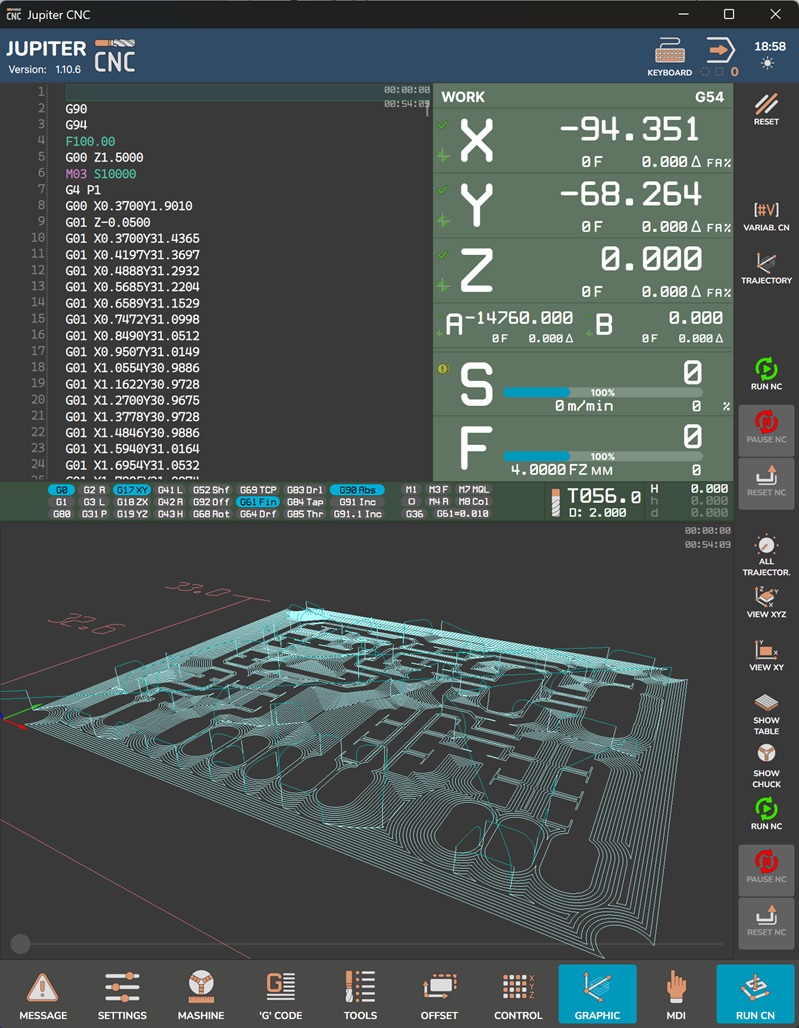

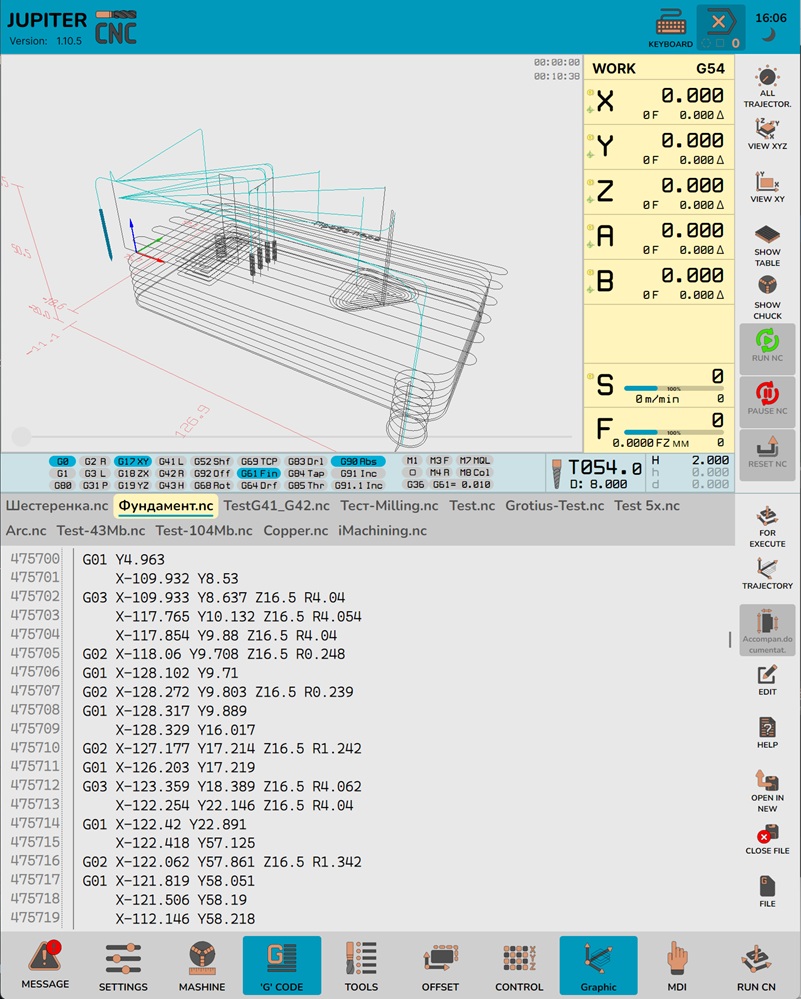

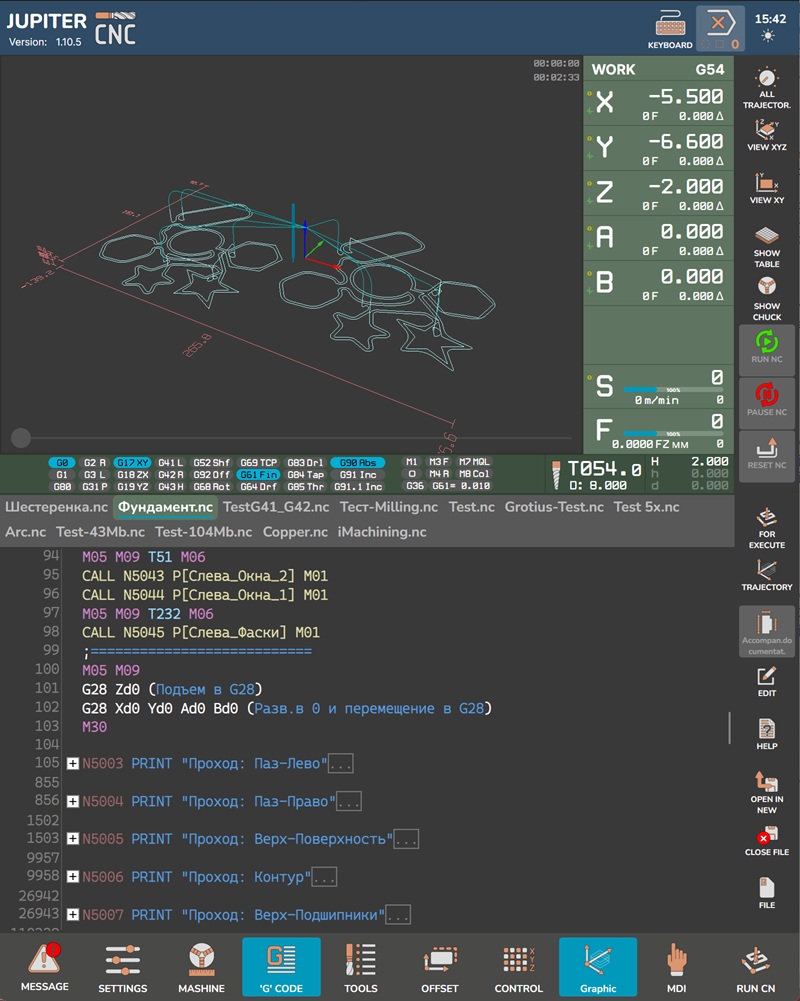

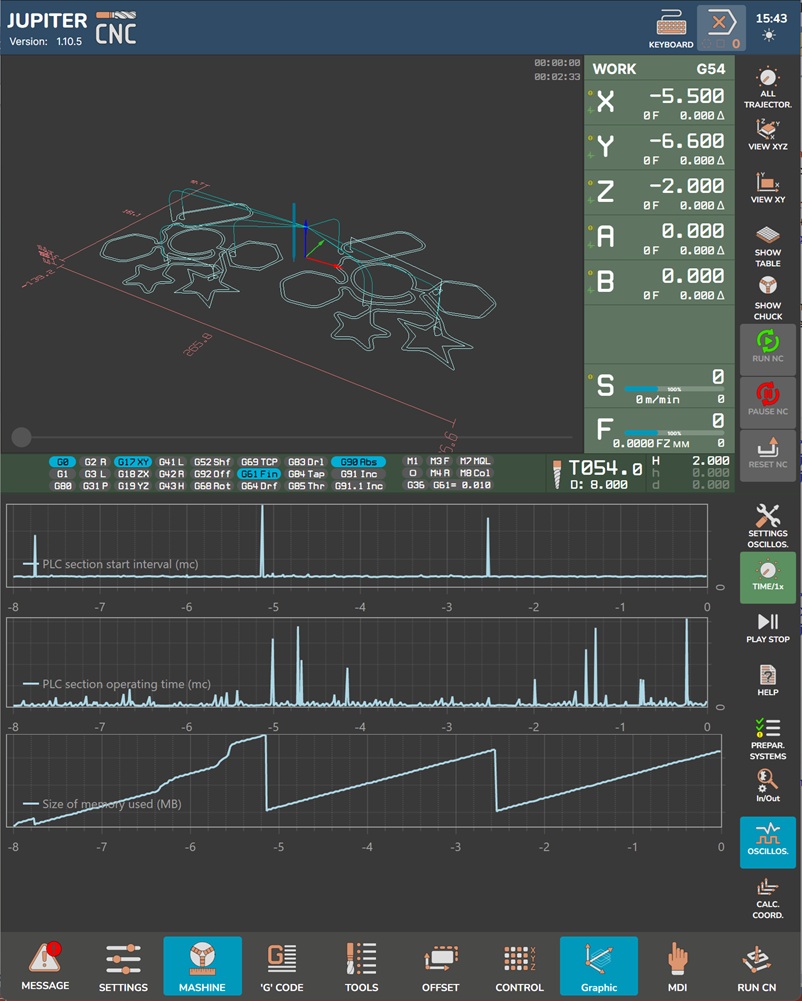

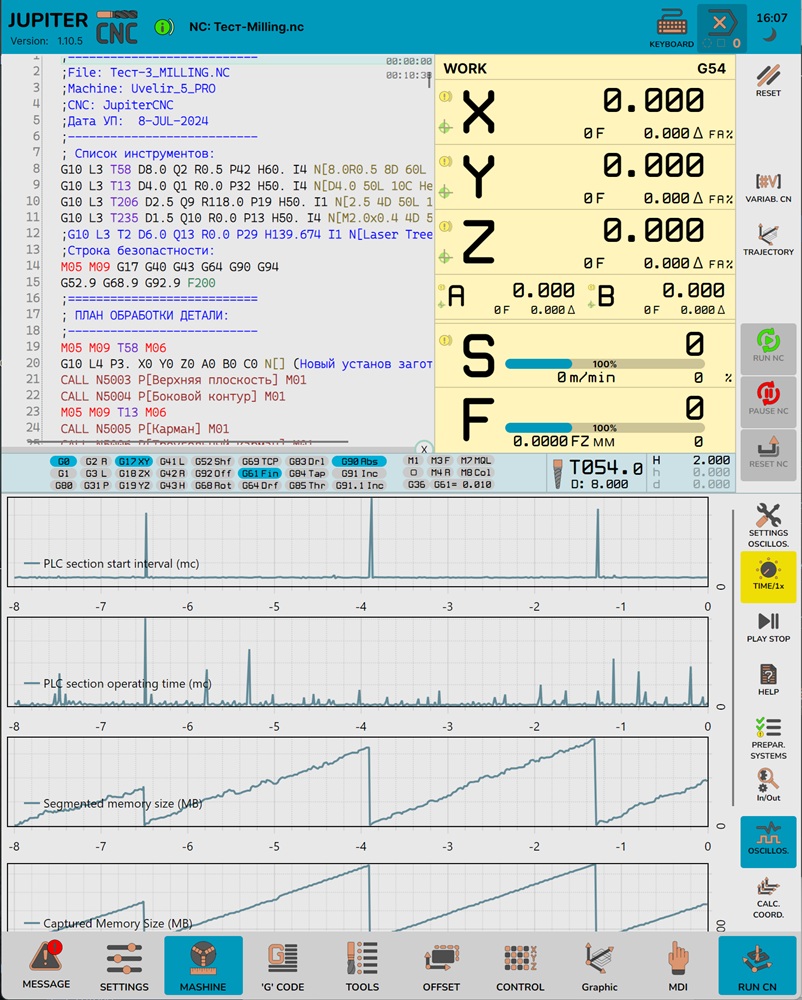

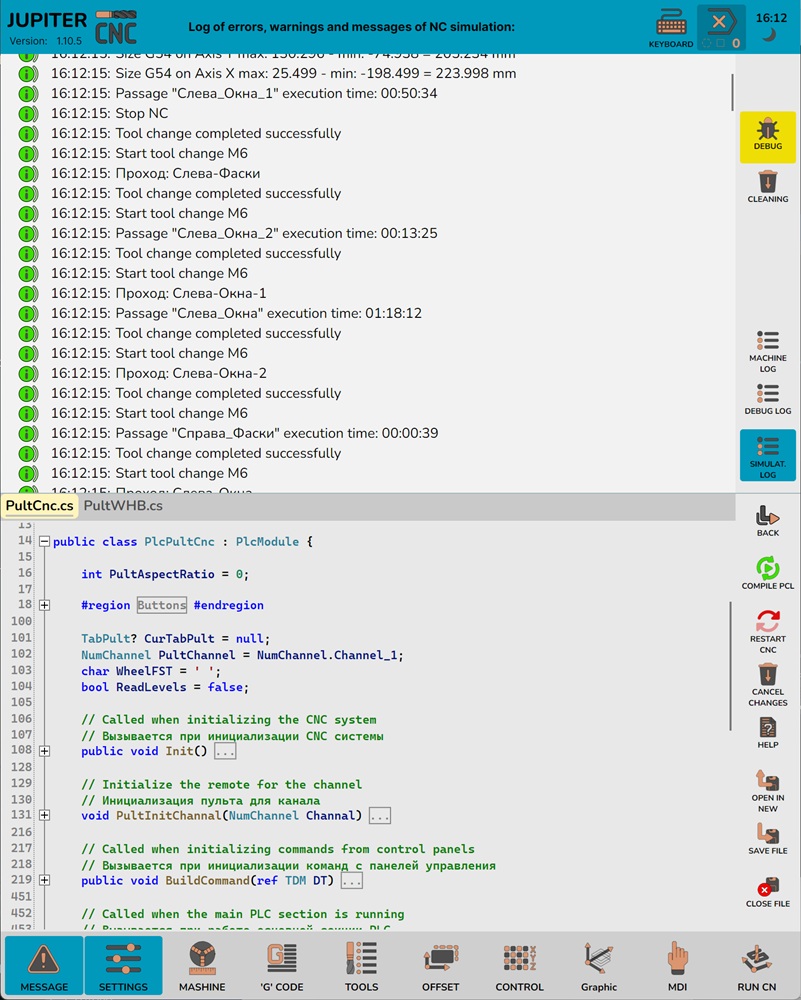

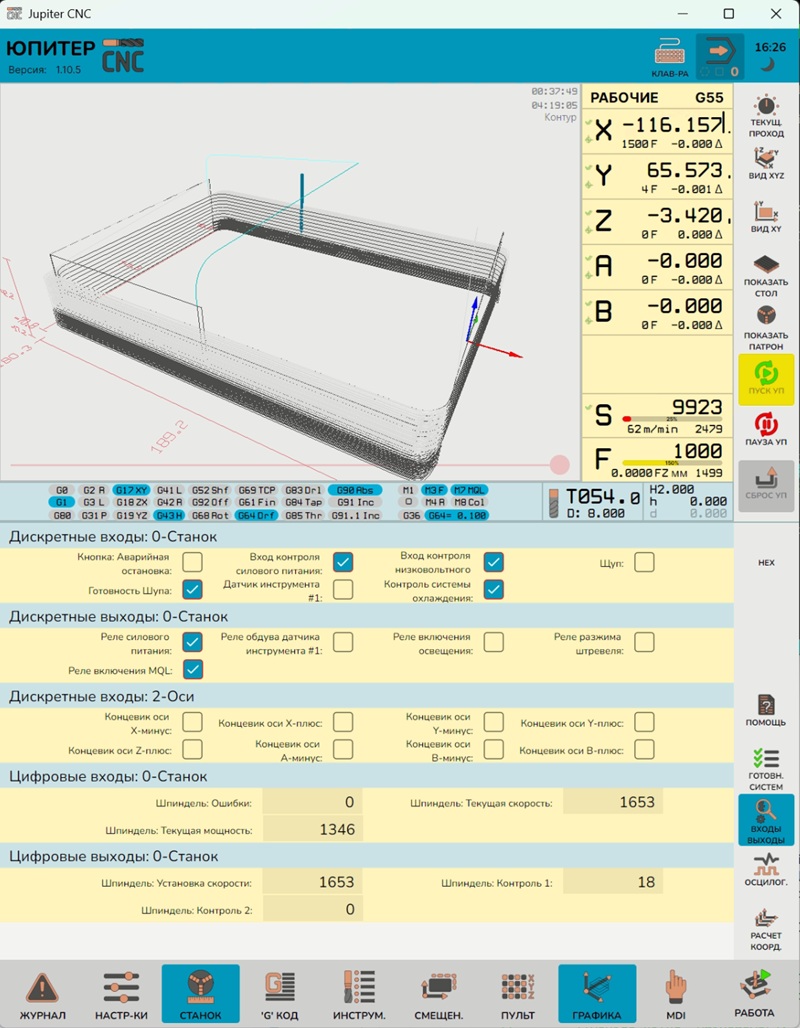

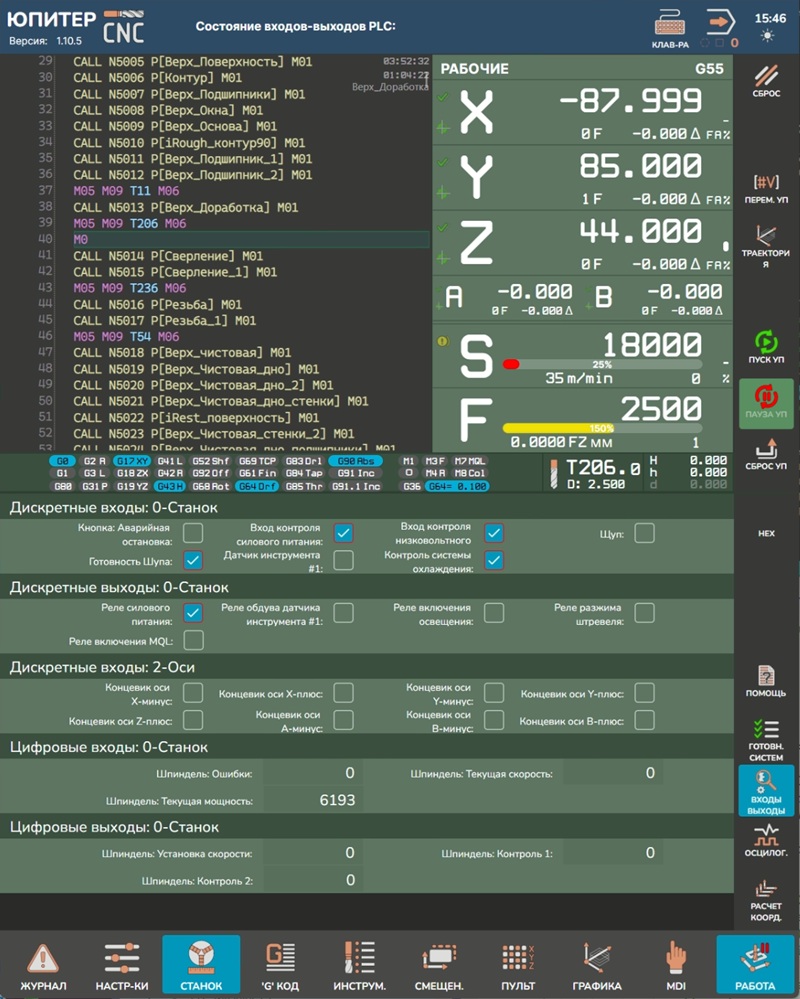

Graphics and control programs:

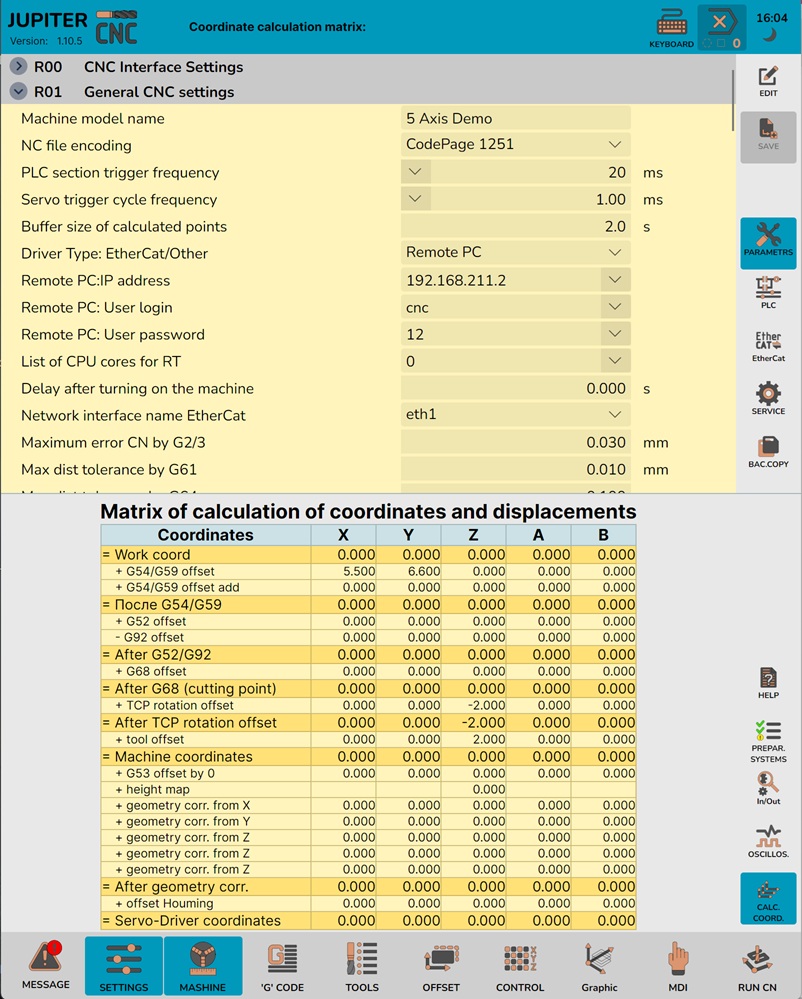

EtherCat settings:

Oscilloscope:

Coordinates and settings:

PLC and messages:

Inputs-outputs:

Two processing channels: